The prepress department at a printing house plays a crucial role in preparing digital files for printing. Here is how we add to your team:

Preflighting: Our team meticulously verifies all manufacturing specifications required for printing. Such as image resolution, color, quality, fonts, and formatting.

Raster Image Processing (RIP): Our specialized software efficiently converts digital files into a format compatible with printing presses. This step guarantees the accurate reproduction of the layout and design.

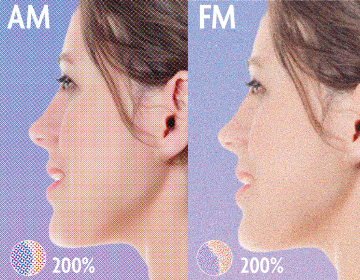

Color Correction and Separation: Adjusting images to achieve the desired color balance and consistency across all print materials.

Proofing: Generating digital proofs for client approval and making adjustments as needed, based on feedback.

Imposition Layouts: Arranging the pages of a layout to ensure efficient use of paper and proper alignment during printing.

Plate Making: Producing printing plates using computer-to-plate (CTP) machines.

Troubleshooting: Resolving any issues that may arise with the digital files, such as file corruption or incompatible formats.