Consultative Solutions

The Royal Paper Box Process

Discovery

With a reputation as a consistent high-quality folding carton manufacturer with outstanding customer service and an on-time delivery record second to none, Royal Paper Box has achieved steady growth and market penetration since 1940.

Solutions Review

Once we’ve decided the best solution options, we prove it by creating a prototype that you can test for product fit and, if needed, request a few added samples for ship testing.

Our talented Sales Representatives will answer any questions about the next steps in your project on remaining development, pricing, and delivery.

Pre-Production Planning

Next, we work with you to set up timelines to ensure we meet every milestone. This planning includes:

-

Finalizing and Approving prototypes

-

Sending Dieline files for Artwork Development

-

Creating and Approving proofs from your Artwork

-

Review of provided specifications

-

Review material requirements

-

Plan optimized route through production

Proofing/Pre- Production Approval

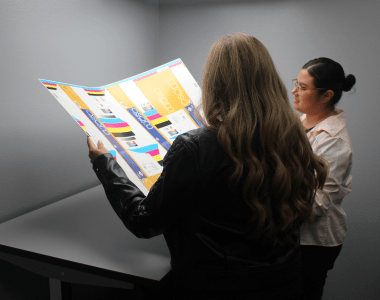

Delivering a quality product that matches your vision is our highest priority. Our skilled PrePress technicians meticulously review approved files to ensure a quality result when your job is ready to print. For your approval, we generate full sized Epson color proofs that accurately replicate your copy and are representative of both copy position and color break. 3D modeling files can also be useful in ensuring that we meet your every expectation.

Quality Control

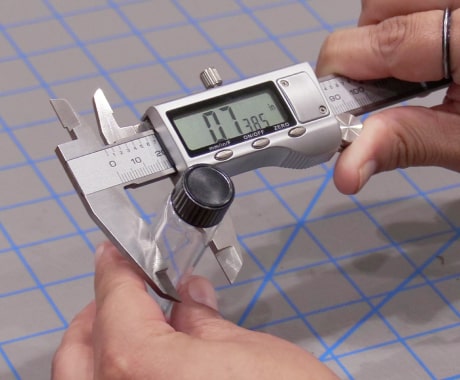

Royal Paper Box’s stringent quality control ensures that your standards are met through thorough checks throughout the production process.

Manage

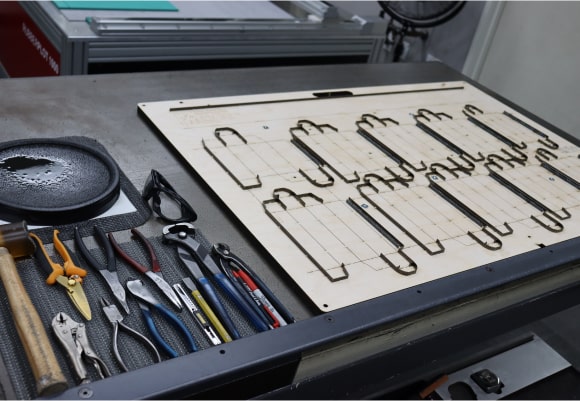

Coordination is critical. Every project, large or small, has details to consider. Items as small as paper selection or printer layout, if not carefully considered, can have lasting impacts on the cost and quality of your operation. For all projects, Royal offers project management services to aid with communication and planning items such as:

-

Periodic team meetings

-

ISO document review

-

Press checks and Acceptance Testing

-

Project scheduling

Customized Production

-

Regulatory compliance aid and verification testing (e.g., performance and composition certification, etc.)

-

Security controls best suited for your needs

-

Line clearances, area segregation and individual product cages throughout the converting process

-

Complete inline text verification

-

Sealed and securely wrapped pallets of finished goods to support FDA/GS1 initiatives

-

Complete chain of custody within a secure production facility.

Shipping and Documentation

Document controls offer you complete product traceability in line with current good manufacturing practices (cGMPs). This process includes:

-

Full raw material and shipment chain of custody

-

First piece validation by internal PCM

-

Certificate of compliance supplied with each shipment

-

Final QC inspection and approval

-

Product record completed with the ERP system

Repeat as Needed

Frequently Asked Questions

If you have a question not addressed here, please click the link below to view more.

View All FAQI haven't worked with you before. Who do I get in contact with at Royal Paper Box for a new project?

What is your lead-time?

Do you have any stock sizes?

What is your minimum order quantity (MOQ)?

How much will my packaging cost?

How can you help me meet our sustainability goals?

What type of recycling program do you have?

Contact Us

Need assistance with your project? Send us a note and our sales team will reach out for more information. We have a structural design and rapid prototyping department that help you.

For immediate attention call us!

Telephone (323) 728-7041

Business Hours

Monday thru Friday

8:00 AM to 5:00 PM

Contact Us

"*" indicates required fields

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply