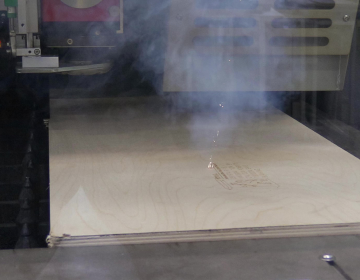

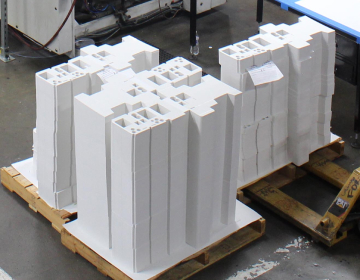

The process starts with designing and creating a die specifically tailored to the carton’s dimensions. At Royal Paper Box, we have our own in-house die-making department equipped with a Penta Laser LTF 2015, ensuring precision and efficiency from the very beginning. Once the durable paperboard is ready, it is fed into a die-cutting machine, where the die cuts the shapes and creates creases for easy folding. After cutting, the excess material is removed and recycled, and the individual cartons are blanked for further processing.

Royal’s Die Cutting Department is equipped with an incredible seven Bobst die-cutting presses ranging from 40″ to 56″ sheet width. Our five Bobst 106PER 42″ presses are equipped with the latest power register technology to ensure that each sheet is cut in near-perfect register, regardless of bounced sheets in printing. Our cutting dies are laser cut and knifed in-house, thereby keeping quality and lead-time under our control.

Why Royal Paper Box?

- Bobst Power Registration ensures accurate print to die cut registration

- Large amount of equipment ensures speed to market

- Bailing system to recycle all scrap/waste